Lyka Smith operates world leading software and simulation systems in order to better plan complex surgeries.

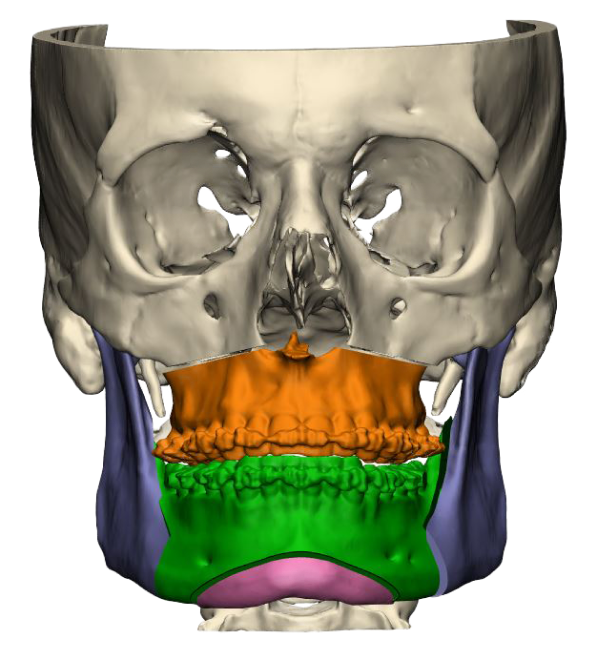

Derived from either CT, CBCT or MRI our surgical planning services combine medical imaging data with computer AI generated design to accurately reconstruct the patient’s anatomy.

Secondary data capture includes intra oral scanning, impression scanning and light/laser scanning to accurately overlay critical anatomical regions not captured in medical imaging data, or to enable a higher degree of data capture outside the capabilities of CT and MRI.

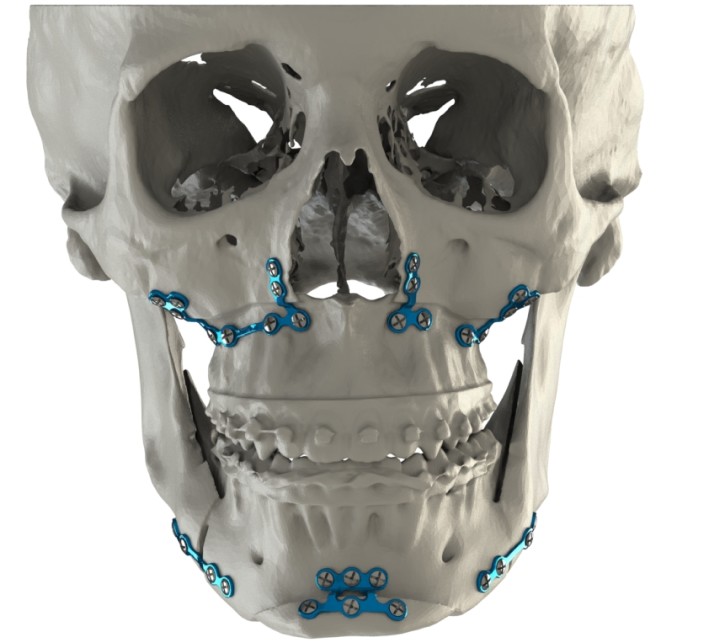

Our data segmentation and is rigorously scrutinised to ensure accuracy at every stage. From there the engineer will be guided by the surgeons specific need for each surgical case. Complex movements, impactions, osteotomies and more can all be planned virtually in minutes.

Product design is surgeon driven, based off each surgeon’s individual needs and preferences for that patient’s case. Lyka Smith engineers manufacture surgical guides in a variety of materials, using both additive and subtractive manufacturing equipment dependant on surgical need.

Lyka Smith operate some of the world’s most advanced 3D printing and CNC milling systems.

Our range of GE Additive Concept Laser Selective Laser Melting systems print in a variety of metals specifically used in medical applications.

The bank of EOS GmbH Selective Laser Sintering polymer printers produce nylon and polymer components capable of high strength, high temperature and sterilisation.

For fine feature details our Stratasys Polyjet biocompatible polymer printers are used. With a print accuracy of 20 microns these printers enable parts, both production and protypes, to be produced with minimal tolerances enabling excellent design to realisation.

Lyka Smith supports a full digital workflow. For those clinicians who have not yet upgraded to an intraoral scanner Lyka Smith offers an intraoral scanning service.

The benefits include:

Lyka Smith 3D prints our medical devices from our Melbourne (Altona North) facility. Our close proximity to Melbourne International Airport enables our rapid production schedule to benefit from expedited courier services both nationally and internationally.

Including all of our metal, high temperature polymer, biocompatible and prototyping systems Lyka Smith operates 16 printing systems.

Yes. Lyka Smith works with surgeons across Australia and internationally to assist them in developing their intellectual property into commercial ideas. For further discussions please email us at [email protected].

Depending on the material requirements Lyka Smith can fabricate a medical device in as little as 3 days from surgeon approval. Delivery location and hospital preferences can determine the overall delivery time however in most cases we are able to supply Australia wide within 5 business days.